For those who are fascinated by these machines and therefore express their interest in purchasing them, there are some aspects to take into consideration, such as: the aesthetic characteristics, which make flywheel slicers a unique element of interior design; the historical period in which the slicer was built; the intended use of the machine; and last but not least, the quality of the restoration process carried out on an authentic piece.

Below you can find a detailed list of six steps to go through as a guide for those who are searching for the ideal restored Berkel slicer – to make sure one makes the right choice in order to meet their own needs and expectations.

1) Aesthetics: the elegance and the unique style of Berkel slicers

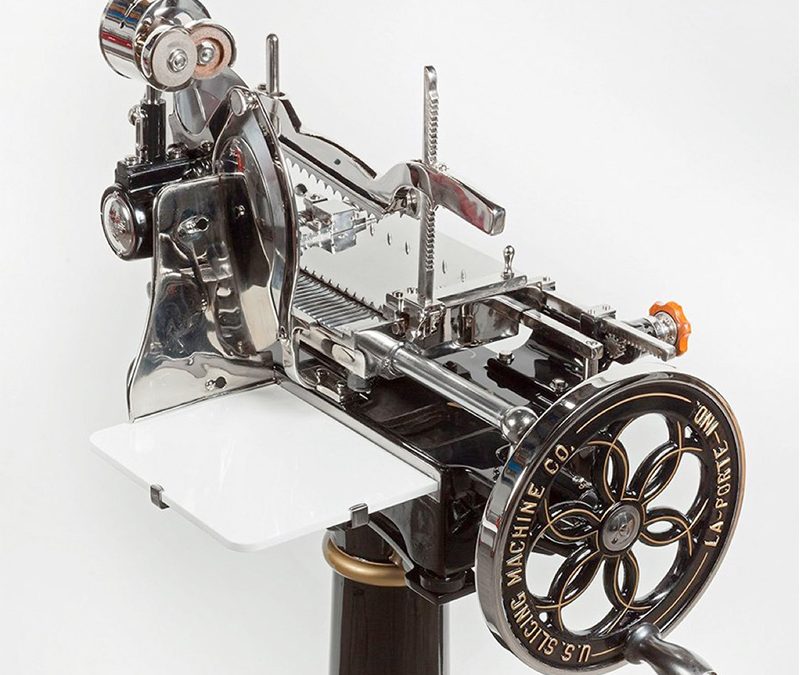

An original restored Berkel slicer has unique aesthetic characteristics, which are the first elements that grab the attention of those who evaluate the purchase of such a machine.

The harmony of the shapes and the details of each model, combined with the colors that distinguish these machines (the classic ones are either red, cream or black, but there is also room for customization), give an unmistakable style to the environments in which they are inserted, both in private homes and in environments intended for the public such as restaurants, delicatessens, wine bars or hotels.

They are, in all respects, furniture components that can complement the best interior design projects also in case these machines have 100 year of history. In fact, through the best restoration process, these machines are brought back to life and their beauty is preserved and magnified.

For these reasons Berkel translates into dedication to elegance and quality. Berkel stands for love of beauty and uniqueness.

2) The context in which a restored authentic Berkel slicer is placed

As already mentioned before, an authentic restored Berkel slicer can be a prestigious piece of furniture both in a private home and in an environment intended for the public.

These slicers represent, beyond the brand, a lifestyle, a passion, and are linked to a set of values of authenticity that are shared by those who know and are part of this world.

Having said that, it is important to say that depending also on the context and the space available, one should evaluate carefully the most suitable model.

You can choose between different models, larger or smaller ones, and all of them represent precious objects that can decorate a loft or a country house.

Among the small models there are some examples, such as the P model, or H9, or even the Berkel model B, called “Indianina” because it was produced only in the state of Indiana in the United States. The latter has small dimensions and is aesthetically beautiful, historic and very rare because it was produced only in two years, from 1919 to 1921.

There are also models of major dimensions that certainly require more space, such as the Berkel 8/21 model.

In addition to the space available, another factor comes into play in the choice of the original restored Berkel slicer, which is the intended use of the slicer, that we will discuss in the next point.

3) The intended use of the restored Berkel slicer

Being aware of the intended use of a Berkel slicer is fundamental, as well as identifying the domestic or commercial reference context, which type of cured meats you want to slice (for example small sizes such as pancetta or carpaccio, or of variable size, even large, such as a sweet cured Parma ham), and how many hours you expect the slicer to be used on average per week.

From the answer to these questions we are able to understand which slicer model is best suited to your needs, with particular attention also to the size of the blades of each model and therefore which ones will allow you to obtain the results you want.

The small machines are beautiful and precise, but generally since they have a blade around 260 mm in diameter, they are suitable for slicing small-sized salami.

A larger slicer, such as the Berkel model 3, which has a 350 mm blade, retains the same aesthetic appeal, and thanks to its larger size it allows you to slice any type of cured meat and is also suitable for commercial use. A professional slicer with a 370 mm diameter blade also has important advantages related to the ease of cleaning, use and precision, since it has been designed for constant use even for several hours a day: we are referring to the 8 /21, and 7 models.

4) Originality, historicity, uniqueness and future value

Thanks to the transition from manual to electric slicers that took place in the 1980-90s, until the early 2000s it was possible to find authentic Berkel machines equipped with all the original components.

This means that people who buy a restored flywheel slicer, which until those years had been used and was in perfect working conditions, now have a 100% original machine in their hands.

Bringing a completely original historical slicer back to life also restores its value, and this is possible if the restoration cycle is careful and detailed.

Originality is necessarily linked to the price. There are Berkel slicers on the market at competitive prices, but if you have a deep look on it, it becomes clear that this apparent advantage is due to the fact that most of these machines are rebuilt with new pieces: in this case the value is not that of the original object.

The historical period also determines the value of the machine. Among the most valuable machines there are the first machines built, those with the flower flywheel, the European Rotterdam Holland slicers and all those produced in Northern Europe in the original Berkel factories.

Then there are the more particular models, of great value too, such as the B 100 model, which is distinguished by an image of two worlds: a plate depicting Europe and America, relating to the award taken by Van Berkel in the 30s as the best producer of flywheel slicers in the world.

Berkel slicers, if original and well restored, constitute an investment whose value increases over time, to guarantee a more and more great satisfaction of the buyer.

5) SAFETY of the restoration process

In machines worn by time it is important that the restoration process includes all the phases that allow them to be restored to their original splendor, also guaranteeing the highest safety standards for food use. This is why we also have a certificate attesting that our chrome plating is suitable for contact with food.

The best process is the one that starts from a copper bath that seals all the pores that show the signs of time and use of the machines. Then a layer of nickel is applied which recovers the original finish of the time. The last phase is that of chrome plating, which, with respect to the Berkel slicers, was introduced in the 1930s. In addition to guaranteeing safety for food use, the last phase concerns an important aesthetic aspect of the slicer, since it gives it the bright silver color. Likewise, painting is crucial, and it must be water-based and not solvent-based, both to ensure the magnificent original appearance of the machine and to ensure its suitability for food use.

6) Why “Original Slicers” is the right supplier for your restored original Berkel slicer

“Original Slicers” is the worldwide reference in the restoration of original Berkel slicers, as it offers authentic pieces, complete with all the original parts and a collection of genuine Berkel slicers that were recovered between the 1980s and the early 2000s , when the manual slicers were passing to electric ones and the first ones still working were abandoned.

Through a proprietary restoration process, designed by our company, we guarantee the perfect functionality and durability of the slicer. We combine the craftsmanship of this restoration process and the skills that our division “Slayer Blades” has built over several years in the production of blades for any type of slicers, distributed all over the world.

Not only do we have rare, unique and exclusive Berkel models, but our strength is that we know all the components in great detail, and we are able to completely restore the slicer, in a detail that foresees even every single screw.

In addition to this all, we guide the customer throughout the process of choosing and evaluating the best solution for their specific needs.

Our passion and our transparency are a guarantee of reliability. Our artisan spirit combined with industrial know-how leads us to be a unique company in the world: just as Van Berkel did in the 1930s – who had won the award as the best producer of slicers in the world, we aim at being recognized as the best of Berkel slicers restorers in the world.