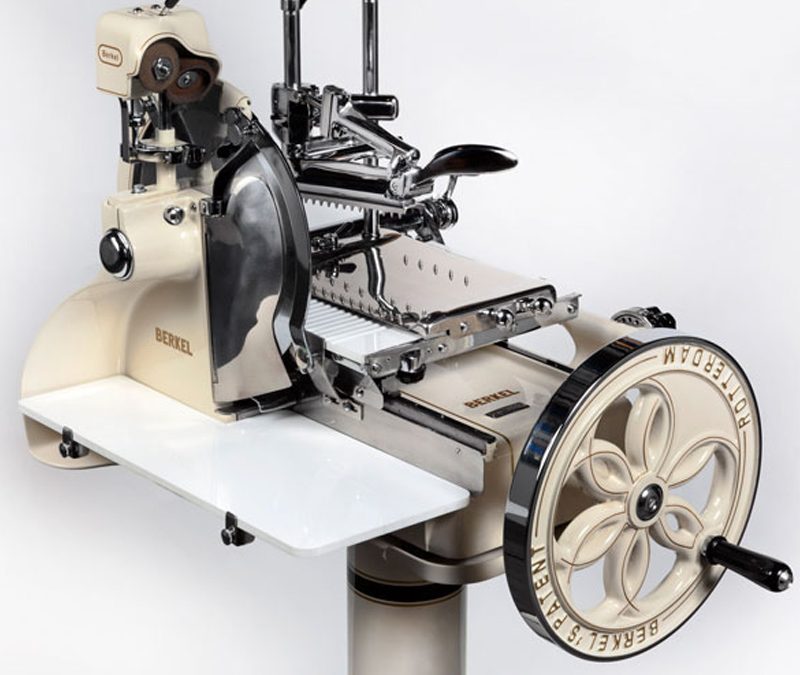

The flywheel – the major element – custom designed for each model of slicer

The flywheel in Berkel manual slicers: a sophisticated and functional gear system

With Berkel flywheel slicers, taste and flavors remain unvaried

The decorations, the flagship of Berkel flywheel slicers

Original Slicers’ Berkel flywheel slicers are unique and original pieces, completely restored by our craftsmen following exclusive artisan methods. These are very valuable slicers, which are subject to a professional restoration cycle, perfected after decades of experience in order to guarantee the slicers’ complete originality, without compromising their correct functioning and precision. Thanks to our methods, we are able to bring back to life the slicers that have worked for decades, allowing Berkel enthusiasts to use them again and immerse themselves completely in the experience that only these meat slicing machines can guarantee.

Our work is continuously recognized by enthusiasts of Berkel flywheel slicers who share the passion towards the use of these manual machines, just as they were designed from the beginning, in the early 1900s.

Our restoration process is studied in detail. The flywheel slicers are disassembled and reassembled respecting all the characteristics and mechanisms of each single meat slicing machine.

Each Berkel flywheel slicer can have up to 700/800 components. Our craftsmen, thanks to their many years of experience, reproduce the correct sequence of disassembly and reassembly of the components based on the model of the machine, thus guaranteeing an excellent final result.

1 The flower flywheel as a valuable feature of the Original Berkel manual slicers

The first machines designed and built by Berkel all had flower flywheels. These slicers are the most valuable of all and all were made before the 1930s, when the slicers still had nickel plating and not chrome plating as they do today.

All our flywheel machines are among the oldest and most valuable on the market. It is useful to list below the models that have made the history of Berkel flywheel slicers, remembering that their value is unique and growing over time.

The first slicer subjected to a real production was the L model – in the years between 1907 and 1916. Then followed the B80 model in the United States, from 1916 to 1919 – the B100 model from 1919 until 1926 – the B model Indianina, the most precious of all, built between 1919 and 1921 – and finally in Europe from 1915 to 1924 model 3 was also made. All these models are of limited and historical production: this greatly affects their value.

2 The flywheel – the major element – custom designed for each model of slicer

The flywheel, for each slicer, represents the “engine” of the machine. The flywheel of these first machines is all flowered and has only a small closed part. The latter acts as a counterweight when the operator manually turns the flywheel, helping him to turn the machine with the same constancy. Flowered flywheel Berkel slicers have an important and scenographic presence. They are functional machines that can become a unique piece of furniture, which does not go unnoticed.

After the production of Berkel flower flywheel slicers, slicers for more professional use were introduced on the market. These slicers, with a full flywheel, are intended for delicatessens, butchers and restaurants that require constant and daily use of the machine. Having this feature, the solid flywheel allows the same performance as the flowered flywheel, having as the only difference the ease of cleaning. Model 8, model 21 and model 9h fall into this category of machines, that is to say all slicers produced on a large scale. Model 8 and model 21 were used at the time in the best gastronomies, and this is also valid today. The slicers with full flywheel guarantee the same performance but are less valuable as more specimens have been produced and present a simpler and more linear decoration.

3 The flywheel in Berkel manual slicers: a sophisticated and functional gear system

The flywheel is the beating heart of every Berkel slicer. It is connected with the different machine components, including the connecting rod, which is an element that, following the manual movement of the flywheel, makes the carriage slide back and forth. Through a second gear, the crown turns the blade, which will slice what is positioned on the trolley.

With the simple movement of the operator’s arm clockwise, the carriage slides back and forth and finally in this way the blade rotates, following the same speed as the flywheel.

We can imagine the flowered flywheel as if it were a clock, since the start of the knob is always at 11:00. For each turn of the flywheel, manually operated by the operator, the blade completes one turn. In Berkel slicers, everything is studied in detail and nothing is left to chance: every gesture and mechanism are in perfect harmony, always guaranteeing a high level of performance and quality.

4 With Berkel flywheel slicers, taste and flavors remain unvaried

The flywheel operating mechanism as described in the previous paragraph guarantees a very important aspect from a gastronomic point of view. In fact, each complete turn of the flywheel corresponds to a complete turn of the cutting blade. This is a notable difference that distinguishes Berkel flywheel slicers compared to electric slicers.

In fact, in the latter (electric machines), the blade performs 16 turns on a slice with an engine speed that can reach 200 revolutions per minute, thus not respecting the 1: 1 ratio typical of Berkel flywheel slicers (1 turn of flywheel, 1 turn of the blade), where a complete turn of the flywheel corresponds to a complete turn of the blade.

This characteristic is typical of our slicers and constitutes an added value for those who use it: in fact, the preservation of taste, odors and flavors is guaranteed. In electric slicers, the blade, turning at higher speeds, alters the taste of the food being sliced, which leads to a change in taste.

In Berkel flywheel slicers, the operator can control the speed of the blade by manually operating the flywheel. Depending on the type of food that will be sliced, the operator can therefore vary the speed, always respecting the tastes and flavors of the food.

The electric slicer does not allow you to slice faster, because the amount of sliced does not depend on the turns of the blade, but on the sliding of the trolley, which is always operated manually.

5 The decorations, the flagship of Berkel flywheel slicers

The decorations of the Berkel flywheel slicers are unique of their kind. The decorations of the machines that are restored by our master craftsmen are reproduced using the same tools that were used then, thus maintaining the originality.

The flowered flywheel is still decorated by hand, with fillet brushes, the ones that were used to decorate precious ceramics: the various rays of the flywheel, the decoration and the embossed writings are reproduced in an exemplary way by hand. The secondary decorations are instead reproduced with an airbrush, which is able to transfer the original decorations meticulously and precisely to the slicer.