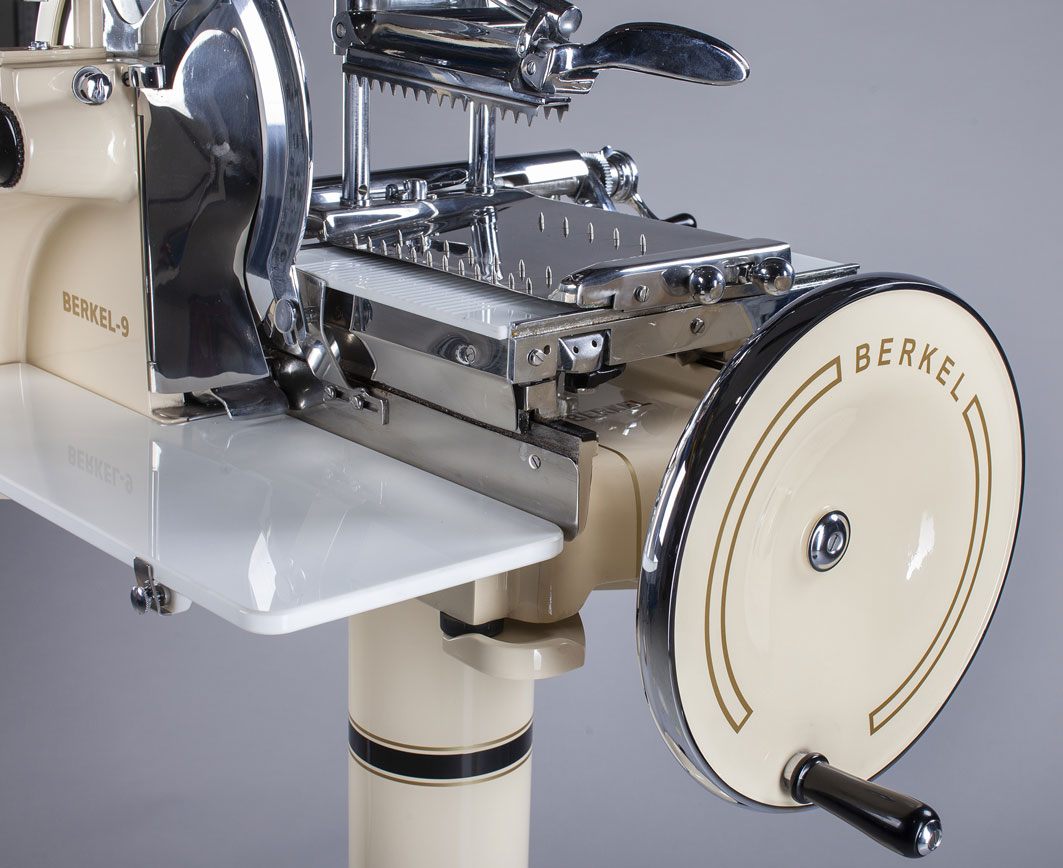

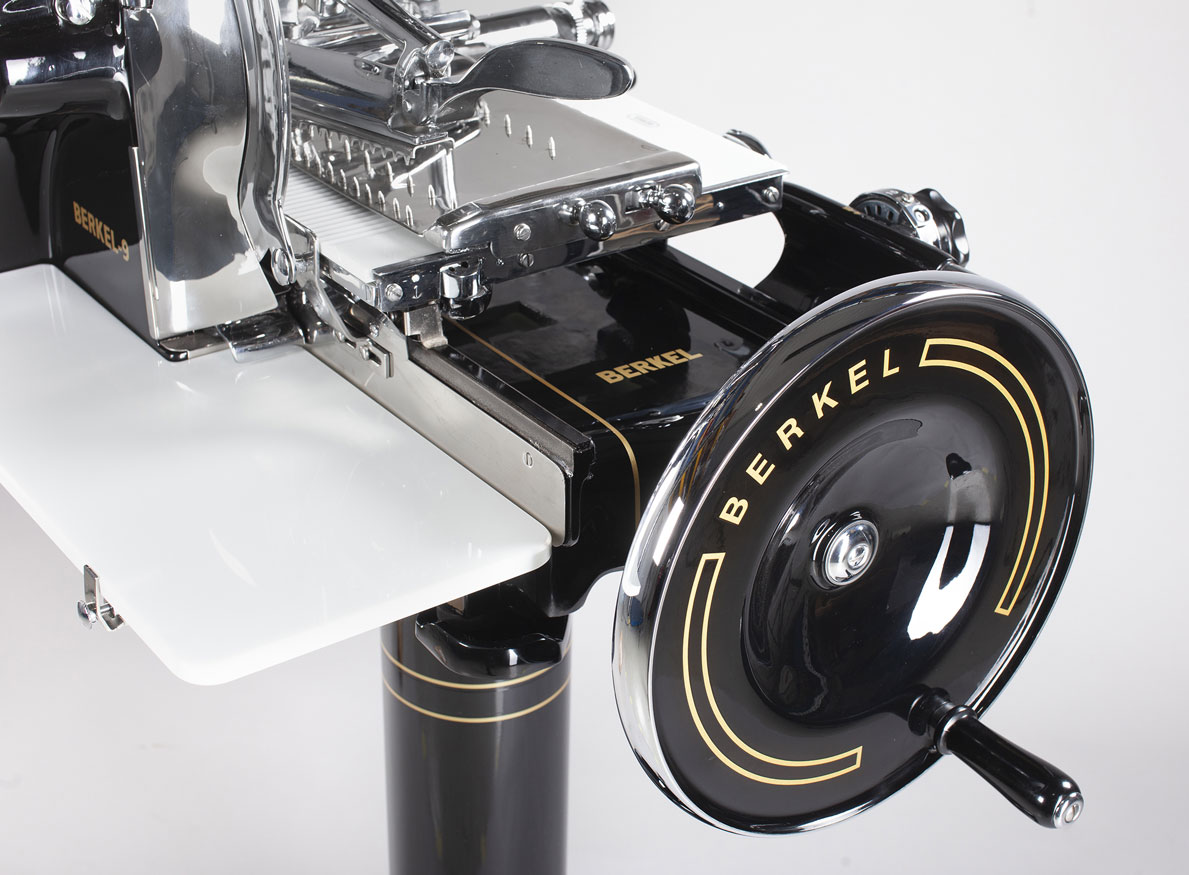

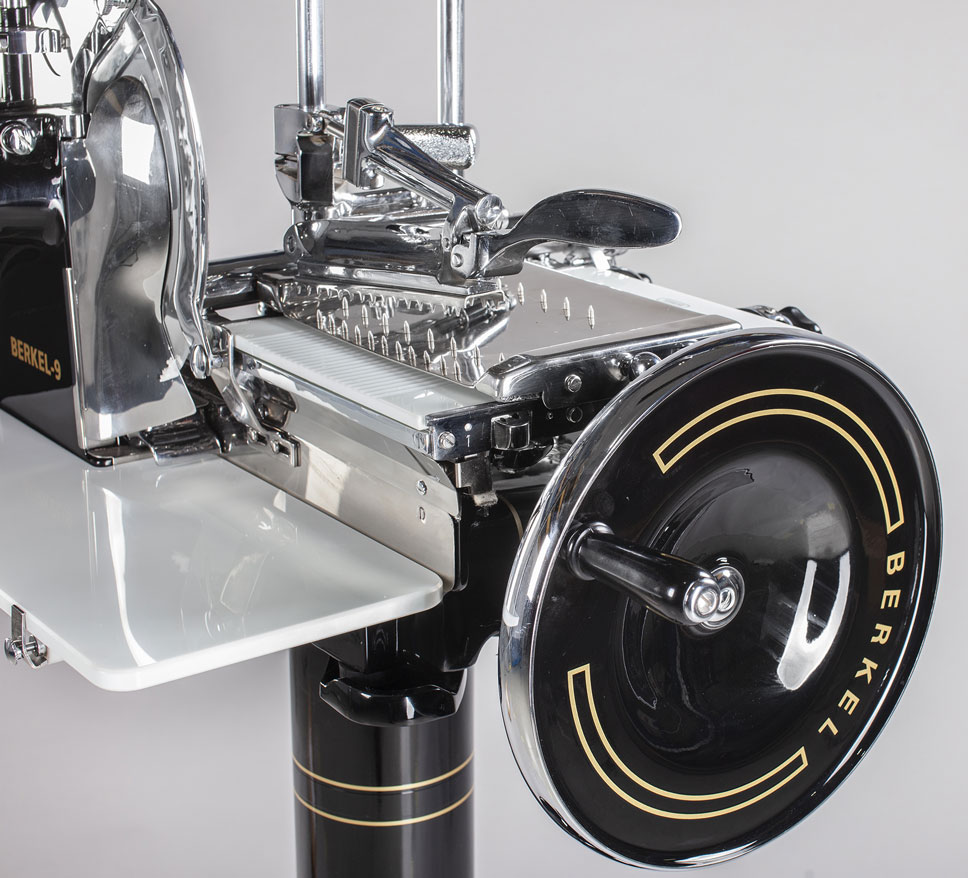

Flywheel slicer Berkel Model 9H

Model:

Berkel 9H

Color:

Black / Cream / Red

Production:

1936 – 1969

Technical data:

Blade: 319

Width: 610

Depth: 830

Height: 600

HISTORICAL NOTES

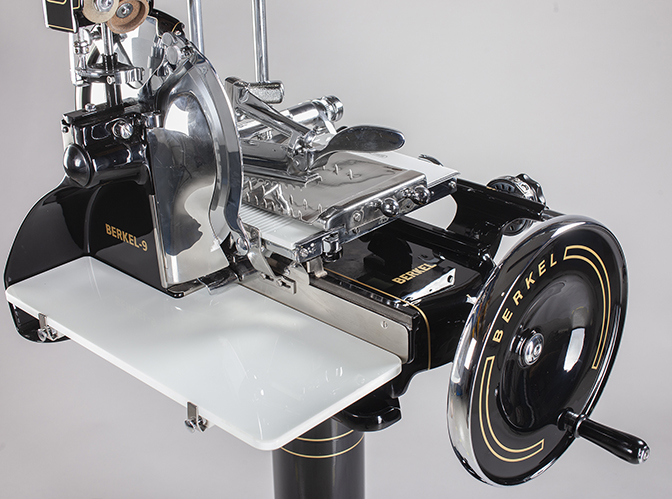

Van Berkel manual slicer Model 9H combines compactness with efficiency.

This model, produced since 1936 and distributed till 1969, could be easily included in the category of the most efficient models, concerning mechanics, and it became the most popular slicer for domestic use. All 9H series have a slicing synchronism similar to models 5 and 7. Nonetheless, the mechanical components of Model 9H were improved in such a way that Van Berkel decided to keep production until the 1960’s.

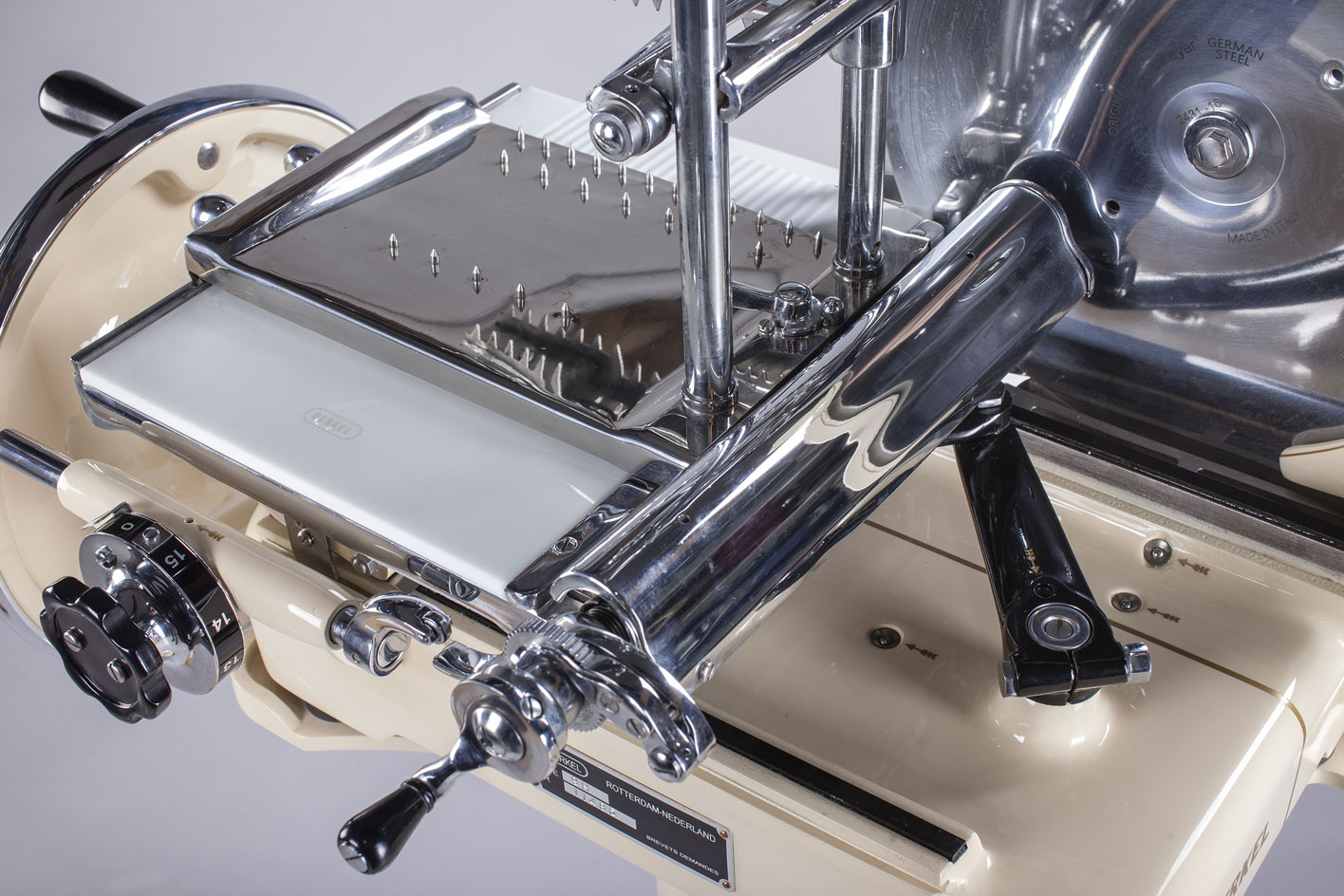

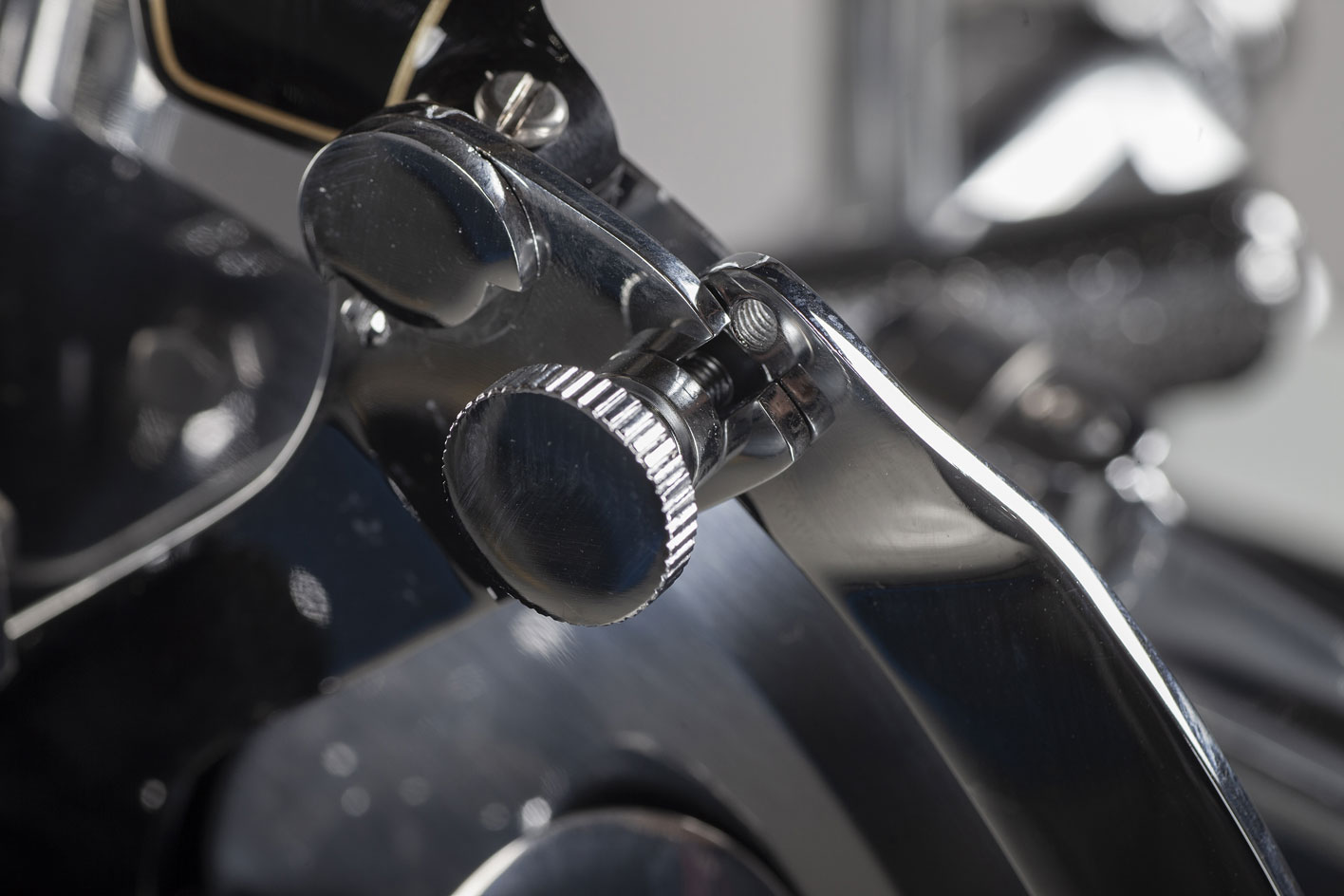

The major change brought by Van Berkel Model 9H manual slicer is related to the worm screw, since there was a shift from the worm screw with ribbed clamp comb to the conical screw. Model 9H, with its pedestal, can be defined as a closed and smooth flywheel meat slicing machine.

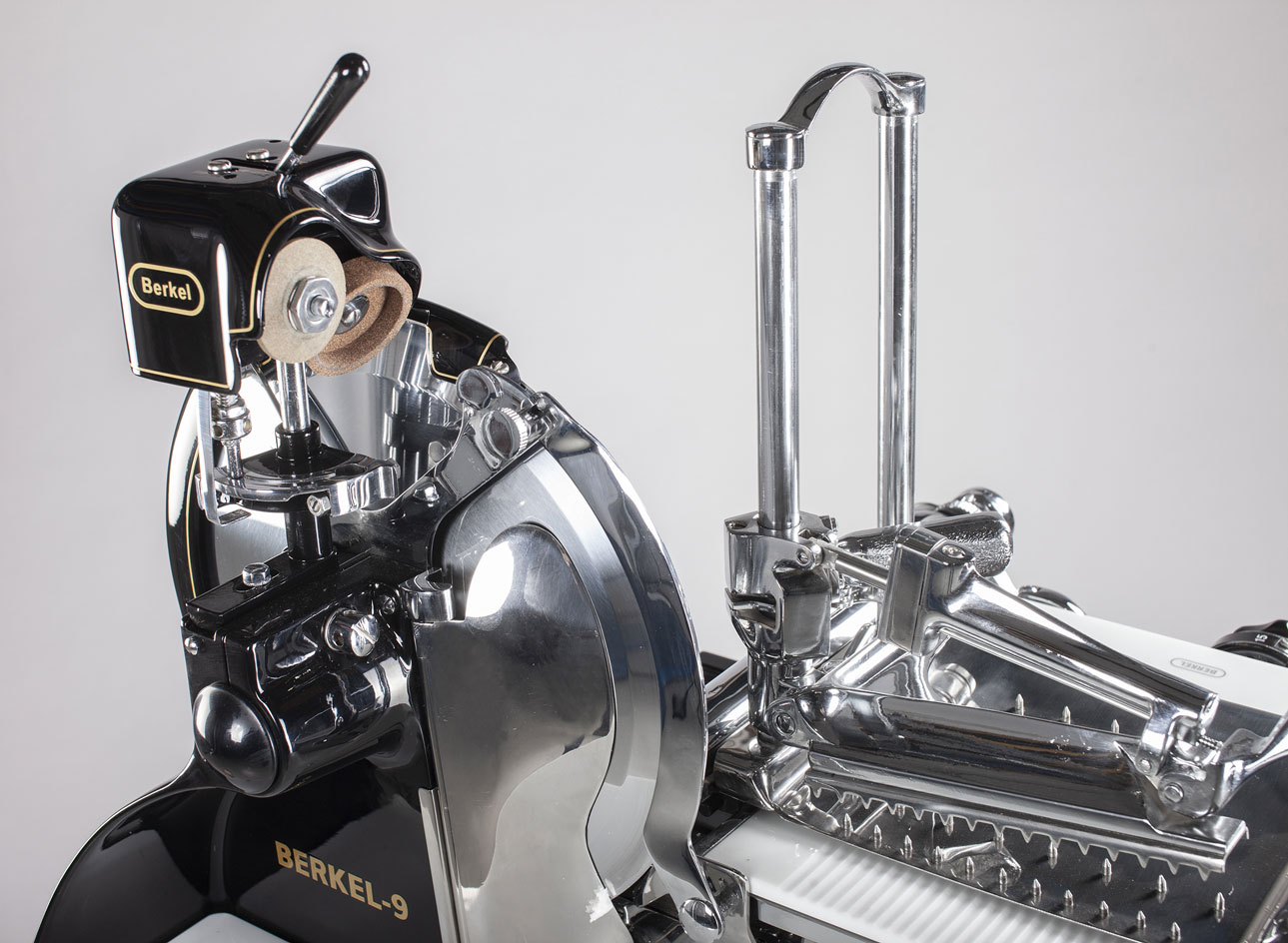

The machine’s comb has twice the contact surface and it is no longer assembled onto the fixing clamp, instead it is mounted on a telescope scrolling headframe, and the comb is positioned in the worm screw at a very high coupling charge. Together with the conical coupling, it compensates the comb wear and allows the best results regarding mechanics and life span of this slicer. A pin pokes out on the headframe where the clamp is positioned and in this model the worm screw and the headframe are covered by a shaped carter.

When in motion the flywheel activates the gears placed at the machine base, which through a chain generate the movement of its 319mm diameter blade, and through two connecting rods start the scroll carriage. The latter moves upon guided wheels on a binary installed at the base of this machine. Slice thickness regulation is possible by means of a peck-shaped lever in axle to the toothed wheel on the scroll carriage. Through a worm screw, the wheel transfers the movement to the comb telescope headframe, which is hooked to the clamp, thus generating the slicing movement. Van Berkel Model 9H features a toothed wheel connected to a lever, which upon activation moves the clamp right or left to reach the desired position.

The hub supporting the blade is located in the machine’s shoulder out flattened side in a wing-shaped bow. By extending the machine’s tray it is possible to increase the working area. The slicer’s sharpener is covered by a painted crown and functions by means of a lever that acts on the cam causing the movement of the two sharpening stones.

Color options start from the classic Van Berkel red, and can be further customized upon request.