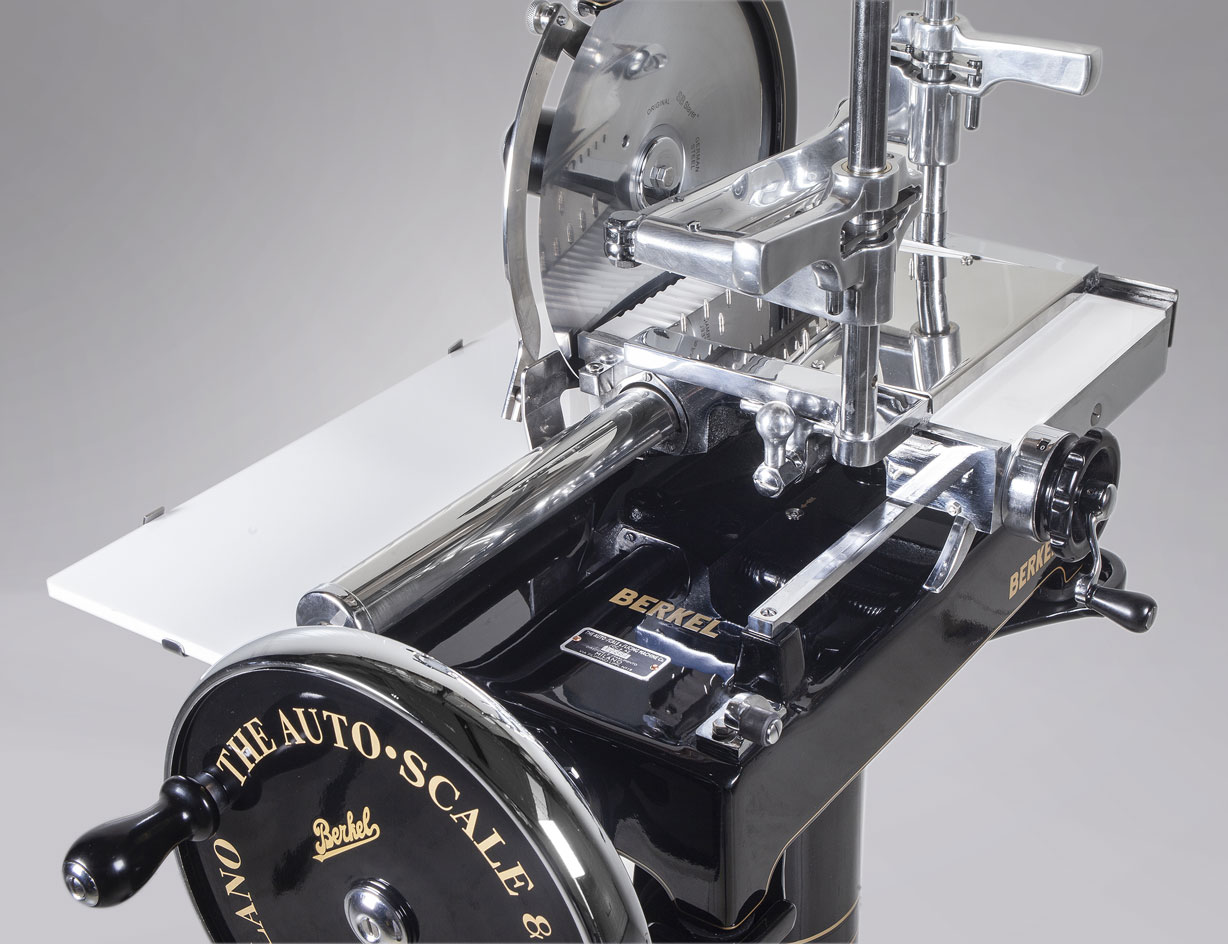

Flywheel slicer Berkel Model P

Model:

Berkel P

Color:

Black / Cream / Red

Production:

1932 – 1936

Technical data:

Blade: 285

Width: 590

Depth: 720

Height: 570

HISTORICAL NOTES

Manufactured between 1932 and 1936, the Van Berkel Model P meat slicer is an “Italian” model, since it was produced exclusively in the company’s establishment of Milan, in Lombardy – Italy. Model P is considered the second smallest manual slicer ever made by Van Berkel, after Model B – or as it is known in Italy, the “Indianina” Model. Its dimensions, including its pedestal, are the perfect solution in case of restrained spaces.

In its first production years, the blade movement of this model was generated by means of a conveying belt: this system was used exclusively on Model P. In this flywheel slicer the fixing clamp for the item being sliced was initially made of two little opposed columns, crossed with friction knobs and gathered by an “L” shaped arm. Later on, during its last production years, the conveying method was switched to a chain, as was happening with other Van Berkel models. The fixing clamp was now open and articulated with guided frictions by two little columns located on the back of the Model P slicing machine.

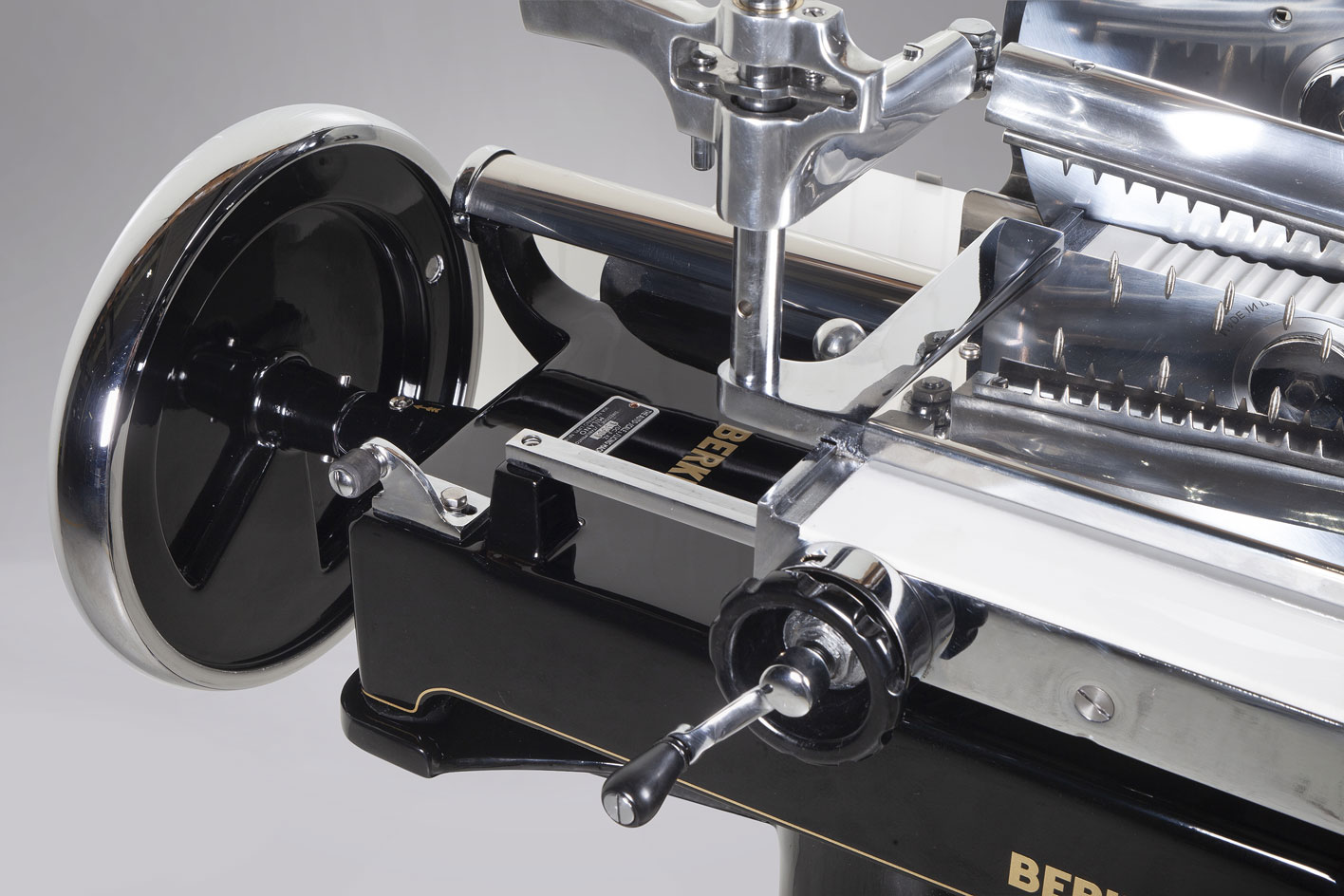

When in motion, Model P’s solid flywheel operates the gears assembly that can be found on the base of the machine. The gears then generate the blade movement, either through a belt or a chain, as well as the scroll carriage, through two connecting-rods. To the blade side, the scroll carriage moves in on a visible pivot, which during the production years was covered by a round carter. On the opposite side, the carriage leans upon a rod through a slide wheel.

Model P’s graduated knob that allows to regulated slice thickness is located on the scroll carriage and has unique characteristics: it is attached to the worm screw with a cog wheel.

This wheel, creates movement by means of a device placed on the manual slicer base thanks to a peck-shaped rod. This motion will then activate the worm screw inserted under the carriage on the front side of the machine, where we may find the machine’s clamp comb. This is how the slicing movement is generated. In this Van Berkel manual slicing machine, the cog-wheel is connected to a lever that is operated in two directions and moves the clamp right or left in order to achieve the desired position. Model P is equipped with a slicer sharpener with small dimensions, hidden by a black crown. Inside the machine shoulder, the blade hub can be found, with a flattened appearance, making a wing-shape bow. This slicer was designed in a way that its tray may be extended, in order to increase the available working surface. In addition to the classic Van Berkel red, further color options may be implemented according to the customers’ preferences.